SERVICE BULLETIN

Issue Date: April 2013 Effective Date: 30 April 2013

SB-42-016-2013 Elevator Bearing Block

SB-42-016-2013-1.0 Page 1 of 3

Subject

Inspection of elevator bearing block and exchange of the Polyamide distances.

Applicability

All IKARUS C42 and C42 B to serial number 1301-7234

By overloading on the ground (support on stick or elevator) or by clearance in the

elevator linkage, the Polyamide distances can cause cracks in the bearing block.

Deadlines

Before the next yearly inspection respectively the next 100h inspection.

Airworthiness Implications

Upon failure of the bearing block the function of the elevator is impaired.

Classification

Service Bulletin, MANDATORY. The actions required as set out below must be

complied with to maintain the airworthiness of the aircraft.

Weight and Balance

Unaffected by inspection requirements.

Electrical loads

Unaffected

SB-42-016-2013-1.0 Page 1 of 3

SERVICE BULLETIN

Issue Date: April 2013 Effective Date: 30 April 2013

SB-42-016-2013 Elevator Bearing Block

SB-42-016-2013-1.0 Page 2 of 3

Actions Required

Maintenance level: Easy

Qualification: Qualified Person

Tools needed: Access to affected component according to the

maintenance manual.

Magnifying glass, tool wrench set, punch, hammer, rivet

gun.

Materials required: Fasteners for attaching the upper fuselage

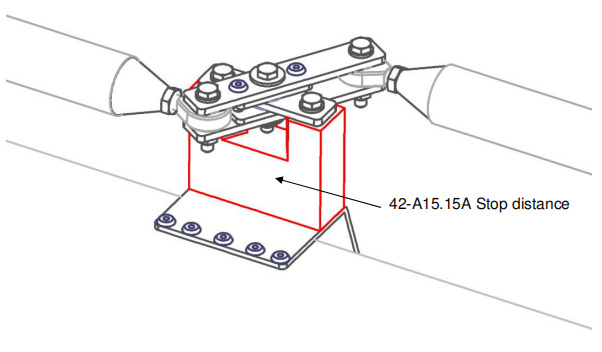

42-A15.15A stop distance elevator balance

42-A01.22 bearing block elevator pushrod

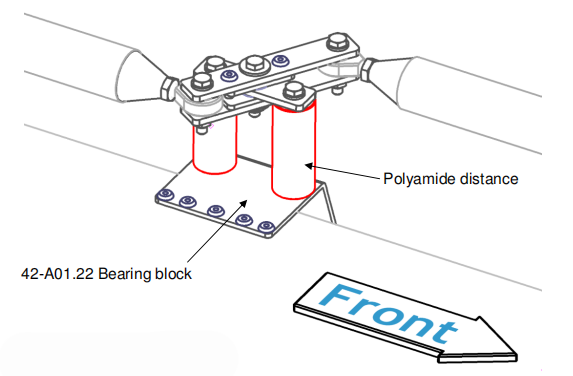

(a) Inspection

Inspection of elevator linkage on stiffness and straightness of the

Polyamide distances. Visual inspection of the elevator bearing block for cracks in

the area of the bend. When in doubt, remove the screws securing the

Polyamide distances for free accessibility of the bearing block.

(b) Repair

Recommended: replacement of Polyamide distances by 42-A15.15A "stop distance

elevator balance "(page 3: images 1 and 2)

When cracks are found in the bearing block: exchange the elevator bearing block.

For this purpose, knock out the steel cores of the rivets into the main tube with a

punch and drill out the rivets.

The bearing block must be replaced with part 42-A01.22 "bearing block elevator

pushrod" and riveted to the main tube.

For this purpose, the included high-strength blind rivets are to be used.

For assembling, new self-locking nuts must be used.

Then the elevator deflections are to be checked upward and downward.

If necessary, the elevator pushrods shall be re-adjusted and secured.

(c) POH Amendment

Unaffected

SB-42-016-2013-1.0 Page 2 of 3

SERVICE BULLETIN

Issue Date: April 2013 Effective Date: 30 April 2013

SB-42-016-2013 Elevator Bearing Block

SB-42-016-2013-1.0 Page 3 of 3

Image 1 previous version

Image 2 new version